-

Industry

Sleek, Smart, Sustainable: The Case for Aluminum Tubes for Cosmetics

Jun 12, 2025

-

Industry

The Best Eco-Friendly Cosmetic Packaging

Apr 01, 2025

-

Industry

The ultimate choice of aluminum bottles for perfume lovers

Apr 01, 2025

-

Industry

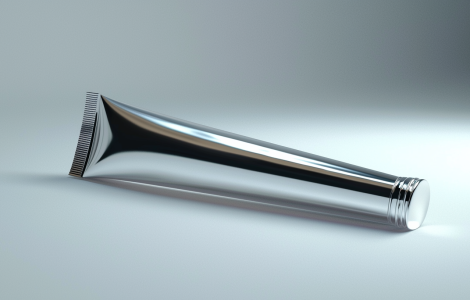

Elegance Redefined: How Metal Squeeze Tubes Elevate Cosmetic Packaging

Feb 01, 2025

-

Industry

Tailored Packaging in Pharma: Balancing Compliance, Safety, and Branding

Feb 01, 2025

-

Industry

Revolutionizing Food Packaging: Top Innovative Design Ideas for Plastic Squeeze Tubes

Jan 25, 2025

-

Industry

Top Trends in Cosmetic Tube Packaging for 2024: Stay Ahead with Cutting-Edge Solutions

Jan 18, 2025

-

Industry

How to Choose the Best Wholesale Toothpaste Tubes for Your Brand: A Comprehensive Guide

Jan 11, 2025

-

Industry

Metal Packaging: Keeping Food Fresh Longer

Dec 28, 2024

The Blog

-

Nov 04, 2024

How Metal Tube Packaging Enhances Product Preservation

Metal tube packaging offers durable protection against environmental factors, extending shelf life and preserving product quality across various industries.

READ MORE -

Jun 12, 2025

Cream Packaging Tubes: Why PE Plastic Is the Smart, Reliable Choice

PE plastic is widely used for cream tubes due to its excellent chemical resistance, flexibility, and recyclability. It provides a safe, affordable, and eco-friendly packaging solution ideal for cosmetics, pharmaceuticals, and personal care products.

READ MORE -

Jun 12, 2025

Sleek, Smart, Sustainable: The Case for Aluminum Tubes for Cosmetics

Aluminum tubes are redefining cosmetic packaging with their high-end aesthetics, excellent barrier protection, and infinite recyclability—making them a top choice for conscious beauty brands.

READ MORE -

Apr 01, 2025

The ultimate choice of aluminum bottles for perfume lovers

The aluminum perfume bottle is shielded from air and UV rays while retaining the fragrance for more than six months. It is perfect for office workers who change their perfume every day or for those who travel frequently and need to carry a luxurious perfume with them.

READ MORE -

Dec 28, 2024

Metal Packaging: Keeping Food Fresh Longer

Metal packaging preserves food by blocking contaminants, extending shelf life, and offering an eco-friendly, recyclable solution.

READ MORE -

Jul 04, 2023

The Art of Cosmetic Packaging Psychology

The psychology of cosmetic packaging plays a significant role in influencing consumer perceptions, emotions, and purchasing behaviors.

READ MORE